-

Solutions

-

-

Materials

-

-

Capabilities

-

RESOURCES

Explore our extensive library of educational content, technical reports, and product information.

CASE STUDIES

dures® XPC-2

Tuff Breed® WSP Extreme® Gold

A497 and A498 Material Blend

CDI Seal Stack Design

Carbon Fiber Reinforced PEEK

dures® A451

CDI installed dures A451 wear rings and bushings in a lean carbonate circulation pump, resulting in an $800,000 increase in yearly production.

dures® 250

CDI’s custom bushings in a seawater circulating pump resulted in doubling of MTBR from two years to four years.

Product Brochures

dures H2O

Drinking Water Systems. Industry Pain Points Solved by High-Performance Polymer Products

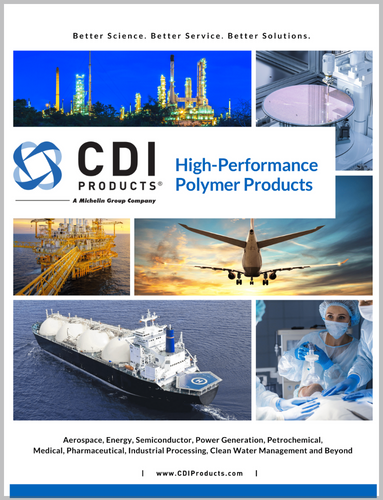

CDI Corporate Brochure

Tuff Breed® Product Brochure

Product brochure for Tuff Breed® line including the SandDog® Header Ring and WSP Extreme® Series product line.

Polymer Products for Compressor Applications Brochure

Our polymeric materials, engineering, and expertise provides compressor manufacturers an invaluable resource.

Polymer Products for Pump Applications Brochure

The dures® range of materials enables pump operators to set tighter clearances, improving reliability, efficiency, and costs.

Polymer Products for Valve Applications Brochure

Performance Product Spotlight - CFT Seals

CDI has been in continuous collaboration with several OEMs in developing an alternate profile with the CFT Seal design.

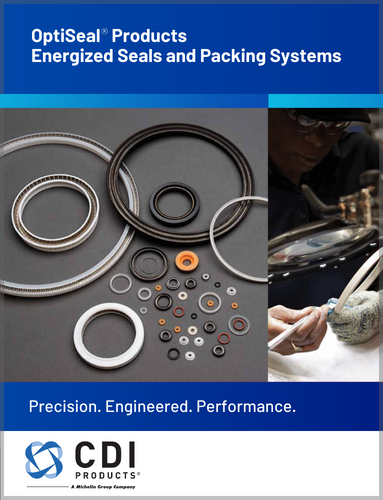

OptiSeal® Products Brochure

OptiSeal® is a versatile, low-friction sealing solution with spring-energized seals, providing improved media compatibility and performance across temperatures.

Elastomeric Seals Brochure

CDI Integrated Capabilities Brochure

EDUCATIONAL GUIDES

Fugitive Emissions: Next-Generation Sealing Solutions

Learn how polymeric, elastomeric, and flexible graphite seals offer distinct advantages to limit harmful gases.

Guide to Thermoplastics

Get an introduction to high-performance polymers as well as the advantages and applications for OEMs.

Setting the Standard in Responsible Manufacturing

CDI is working hard to set the standard in responsible manufacturing. See the steps we're taking to reducing our overall environmental impact by 30% by 2030.

5 Benefits of Vertical Integration in Manufacturing

OEMs have a choice when sourcing a manufacturing partner. Discover how a streamlined approach to product manufacturing reduces costs and improves quality.

How Smart Manufacturing Is Transforming Factories

Smart manufacturing is restructuring the landscape. Learn how innovative manufacturers are leveraging data and analytics to move faster while lowering costs.

6 Benefits of Converting Metal Components to Plastic

Today's plastics are increasingly popular with OEMs. Find out how to save time and increase efficiency by switching from metal to high-performance engineered thermoplastics.

Why You Should Consider Plastics Over Metals

Before choosing a material for your next project, see what today’s plastics can do. This highly visual infographic shows four reasons for considering plastics over metals.

Innovative Sealing Solutions for Today's Oil and Gas Industry

Improve your operations with polymer and flexible graphite components that meet your most critical challenges.

CDI Products Quality Policy

We are committed to meeting the needs and expectations of our customers. We will achieve this by understanding our customers’ requirements and by employing a culture of operational and business excellence that embraces continuous improvement of our processes and products.

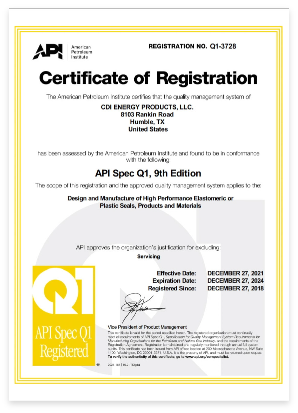

API Specification Q1

American Petroleum Institute certification of the CDI Quality Management System for the Design and Manufacture of High-Performance Elastomeric or Plastic Seals, Products, and Materials.

AS9100D - Aerospace Industry Quality Certification

Certificate of Approval for Design and Manufacture of Seals and other Products from High-Performance Elastomers, Plastic, Composite, and Metal Materials for Aerospace and Industrial Applications.

ISO 9001:2015

Certification from the American Petroleum Institute Quality Registrar for the Design and Manufacture of High-Performance Elastomeric or Plastic Seals, Products, and Materials.

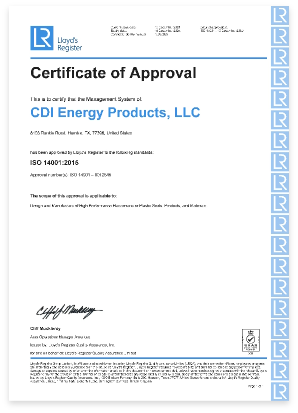

ISO 14001:2015

ISO 14001:2015 certification for the Design and Manufacture of High-Performance Elastomeric or Plastic Seals, Products, and Materials.

ISO 45001:2018 Certification

ISO 45001:2018 certification for the Design and Manufacture of High-Performance Elastomeric or Plastic Seals, Products, and Materials.

HSSE Policy

CDI's Health, Safety, Security, and Environmental (HSSE) Management System Policy.

TECHNICAL REPORTS

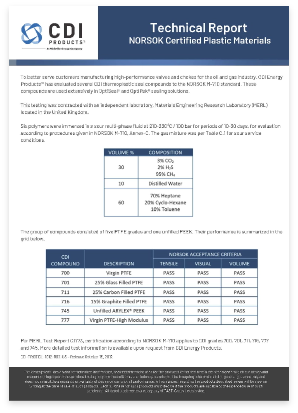

NORSOK M-710 Plastics

View the evaluation of several CDI thermoplastic seal compounds to the NORSOK M-710 standard. These compounds are used extensively in OptiSeal® and OptiPak® sealing solutions.

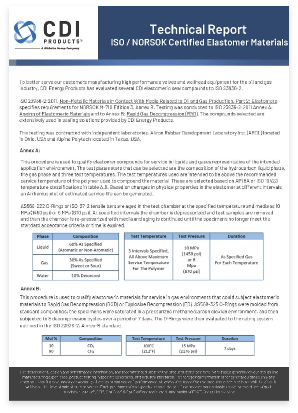

Norsok M-710 / ISO 23936-2 Elastomers

View the evaluation of several CDI elastomeric seal compounds to ISO 23936-2. The compounds selected are extensively used in sealing solutions provided by CDI.

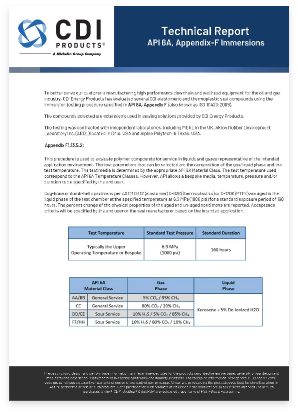

API 6A Annex F Polymers

View the evaluation of several CDI elastomeric and thermoplastic seal compounds using the

immersion testing procedure known as ISO 10423:2009.

Material Data Sheets

27-1840

COMPOUND: 27-1840

POLYMER: Polyamide (PA)

DESCRIPTION: Unreinforced Nylon 11, Natural; Injection molded Stock Shapes and Machined parts

4472

COMPOUND: 4472

POLYMER: Nitrile Rubber (NBR)

DESCRIPTION: 73a Black – Aerospace Grade per MIL-PRF-25732E, QPL listed

4510

COMPOUND: 4510

POLYMER: Carboxylated Nitrile Rubber (NBR)

DESCRIPTION: 83a Black – Aerospace Grade

6680

COMPOUND: 6680

POLYMER: Fluorosilicone

DESCRIPTION: 70a Blue – Aerospace Grade Designed to Meet MIL-DTL-25988C Type 1/Class 1

700

COMPOUND: ARMORLENE® 700

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: Unfilled PTFE, Compression Molded Stock Shapes and Machined parts

700-7AX

COMPOUND: 700-7AX

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: Unfilled PTFE, Compression & Isostatic Molded Stock Shapes and Machined parts

700NI4

COMPOUND: 700NI4

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: A Proprietary PTFE Compound Filled with Nickel Powder, Compression Molded Stock Shapes and Machined parts

700RE

COMPOUND: 700RE

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: Unfilled PTFE, Ram Extruded Stock Shapes and Machined parts

701

COMPOUND: 701

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: 25% Glass Fiber Reinforced PTFE, Compression and Isostatic Molded Stock Shapes and Machined parts

702 (A173)

COMPOUND: ARMORLENE® 702 (A173)

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: 15% Glass Fiber Reinforced and 5% MoS2 (Moly) Filled PTFE Compound, Compression Molded Stock Shapes and Machined parts

703

COMPOUND: 703

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: A Proprietary PTFE Compound Filled with PPS, Carbon, and MoS2 (Moly), Compression Molded Stock Shapes and Machined parts

706

COMPOUND: 706

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: 15% Glass Fiber Reinforced PTFE Compound, Compression Molded Stock Shapes and Machined parts

711

COMPOUND: 711

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: 25% Carbon-Graphite Filled PTFE, Compression and Isostatic Molded Stock Shapes and Machined parts

711FF

COMPOUND: 711FF

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: 25% Carbon-Graphite Filled PTFE, Compression & Auto Molded Stock Shapes and Machined parts

714

COMPOUND: 714

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: Bronze-Moly (MoS2) Filled PTFE, Compression and Isostatic Molded Stock Shapes and Machined parts

716

COMPOUND: ARMORLENE® 716

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: 15% Graphite Filled PTFE Compound, Compression Molded Stock Shapes and Machined parts

727

COMPOUND: 727

POLYMER: Polyamide (PA)

DESCRIPTION: 30% Glass Fiber Reinforced Nylon 6/6, Natural. Stock Shapes and Machined parts

729

COMPOUND: 729

POLYMER: Polyamide (PA)

DESCRIPTION: Unfilled Nylon 66 (PA), Extruded Stock Shapes and Machined parts, Yellow Colored

734

COMPOUND: 734

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: 10% Carbon-Graphite Filled PTFE, Compression and Isostatic Molded Stock Shapes and Machined parts

745

COMPOUND: ARYLEX® 745 (Formerly designated as Xytrex 450 Injection Molded)

POLYMER: Polyetheretherketone (PEEK)

DESCRIPTION: Unfilled (Virgin) PEEK, Injection molded finish parts, stock shapes, and machined parts

745R

COMPOUND: ARYLEX® 745R

POLYMER: Polyetheretherketone (PEEK)

DESCRIPTION: Unfilled PEEK, Injection molded finish parts, stock shapes, and machined parts

748

COMPOUND: 748

POLYMER: Ultra High Molecular Weight Polyethylene (UHMW-PE)

DESCRIPTION: Ultra High Molecular Weight Polyethylene (UHMW-PE) Compression Molded & Extruded Stock Shapes and Machined parts

748HT

COMPOUND: 748HT

POLYMER: Ultra High Molecular Weight Polyethylene (UHMW-PE)

DESCRIPTION: High Operating Temperature Ultra High Molecular Weight Polyethylene (UHMW-PE) Compression Molded & Extruded Stock Shapes and Machined parts

748OF

COMPOUND: 748OF

POLYMER: Ultra High Molecular Weight Polyethylene (UHMW-PE)

DESCRIPTION: Oil Filled Ultra High Molecular Weight Polyethylene (UHMW-PE) Extruded Stock Shapes and Machined parts

754

COMPOUND: ARYLEX® 754

POLYMER: Polyetheretherketone (PEEK)

DESCRIPTION: 30% Carbon Fiber Reinforced PEEK, Injection molded finish parts, stock shapes, and machined parts.

757

COMPOUND: 757

POLYMER: Polyamide (PA)

DESCRIPTION: MoS2 Filled Nylon 6/6 (PA), Extruded Stock Shapes and Machined parts

773

COMPOUND: 773

POLYMER: Polyamide (PA)

DESCRIPTION: Nylon 6/12 unfilled, Cast Stock Shapes and Machined parts, Yellow Colored

773D

COMPOUND: 773D

POLYMER: Polyamide (PA)

DESCRIPTION: Devlon V-API Nylon 12/6 unfilled, Cast Stock Shapes and Machined parts, Yellow Colored

777

COMPOUND: ARMORLENE® 777

POLYMER: Polyetheretherketone (PEEK)

DESCRIPTION: Unfilled Modified PTFE, Compression Molded Stock Shapes and Machined parts

782

COMPOUND: 782

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: Carbon Fiber Reinforced and Lubricated MPTFE Compound, Compression Molded Stock Shapes and Machined parts

798

COMPOUND: 798

POLYMER: Polyamide (PA)

DESCRIPTION: Oil Filled Nylon 6, Cast Stock Shapes and Machined parts, Green Colored

799

COMPOUND: 799

POLYMER: Polyamide (PA)

DESCRIPTION: Unfilled Nylon 6 Natural, Cast Stock Shapes and Machined parts

799E

COMPOUND: 799E

POLYMER: Polyamide (PA)

DESCRIPTION: Unfilled Nylon 66 (PA) Natural, Extruded Stock Shapes and Machined parts

9973

COMPOUND: 9973

POLYMER: 9973

DESCRIPTION: 75a Black – Aerospace Grade Designed to Meet AMS7379

9974

COMPOUND: 9974

POLYMER: FKM

DESCRIPTION: 75a Black – Aerospace Grade Designed to Meet AMS7410

A50F

COMPOUND: A50F

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: Polymer Filled PTFE Compound, Compression and Isostatic Molded Stock Shapes and Machined parts

A66

COMPOUND: A66

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: Mineral & Molybdenum Disulfide (MoS2) Filled PTFE, Compression & Isostatic Molded Stock Shapes and Machined parts

A71BLKFF

COMPOUND: A71BLKFF

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: Glass Fiber Reinforced PTFE, Black Colored, Ram Extruded Stock Shapes and Machined parts

A76

COMPOUND: A76

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: Glass Fiber Reinforced & MoS2 Filled, Green Colored PTFE Compound, Compression Molded Stock Shapes and Machined parts

A90

COMPOUND: A90

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: Carbon-Graphite Filled PTFE, Compression and Isostatic Molded Stock Shapes and Machined parts

A103BLUE

COMPOUND: A103BLUE

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: 15% Glass Fiber Reinforced PTFE Compound, Blue Colored

A451

COMPOUND: ARYLEX® A451

POLYMER: Polyetheretherketone (PEEK)

DESCRIPTION: 30% Carbon Fiber Reinforced PEEK Compound. Compression molded stock shapes and machined parts

A457

COMPOUND: ARYLEX® A457

POLYMER: Polyetheretherketone (PEEK)

DESCRIPTION: Bearing and Wear grade PEEK Compound. Compression molded stock shapes and machined parts.

A642

COMPOUND: A642

POLYMER: Polyphenylene Sulfide (PPS)

DESCRIPTION: Carbon & PTFE Filled PPS Bearing Grade Compound, Compression and Ram Extruded Stock Shapes and Machined parts

A673

COMPOUND: A673

POLYMER: Polyetheretherketone (PEEK)

DESCRIPTION: Carbon Fiber Reinforced PEEK Compound

dures 150

dures® 150 Non-Metallic Wear Material for Pump Applications

Grade Number: PJ00M

Material references: dures® 150, A655

Polymer Family: PPS (Poly Phenylene Sulfide)

Description: Bearing Grade PPS - Compression Molded Stock Shapes and Machined Parts

dures 200

dures® 200 Non‐Metallic Wear Material for Pump Applications

Grade Number: FCC4A

Material References: dures® 200

Polymer Family: PFA (Perfluoroalkoxy)

Description: Carbon Fiber Reinforced PFA Compound – Compression Molded Stock Shapes and Machined Parts.

dures 250

dures® 250 Non-Metallic Wear Material for Pump Applications

Grade Number: KCP0A

Material References: dures® 250

Polymer Family: PEEK (Poly Ether Ether Ketone)

Description: High Abrasion Resistant Proprietary PEEK Compound – Compression Molded Stock Shapes and Machined Parts

dures A451

dures® A451 Non-Metallic Wear Material for Pump Applications

Grade Number: KJC3A

Material References: dures® A451, 754C, Arylex 451

Polymer Family: PEEK (Poly Ether Ether Ketone)

Description: Carbon Fiber Reinforced PEEK ‐ Compression Molded Stock Shapes and Machined Parts

dures H2O

dures® H2O

Compound: dures® H2O

Polymer: Polyphenylene sulfide (PPS)

Description: Bearing Grade PPS Compound. Material complying with NSF/ANSI/CAN 61 requirements for Drinking Water System Components – Health Effects. Compression Molded Stock Shapes & Machined Parts.

dures XPC-2

dures® XPC-2 Non-Metallic Wear Material for Pump Applications

Number: CW50B

Material References: dures® XPC‐2, XC‐2

Polymer Family: PEEK (Poly Ether Ether Ketone)

Description: Filament Wound PEEK / Continuous Carbon fiber composite

EX1414

COMPOUND: EX1414

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: Proprietary Filled PTFE, Compression and Isostatic Molded Stock Shapes and Machined parts

LX111

COMPOUND: LX111

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: Wear Resistant Filled PTFE Compound, Compression, Isostatic and Auto Molded Stock Shapes and Machined parts

LX116

COMPOUND: LX116

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: Wear Resistant Filled PTFE Compound, Compression, Isostatic and Auto Molded Stock Shapes and Machined parts

LX332

COMPOUND: LX332

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: Wear Resistant Filled PTFE Compound, Compression, Isostatic and Auto Molded Stock Shapes and Machined parts

LX374

COMPOUND: LX374

POLYMER: Polytetrafluoroethylene (PTFE)

DESCRIPTION: Wear Resistant Filled PTFE Compound, Compression, Isostatic and Auto Molded Stock Shapes and Machined parts

NJG4A

COMPOUND: NJG4A

POLYMER: Polyamide (PA)

DESCRIPTION: 40% Glass Fiber Reinforced Natural Nylon 6, Injection molded Stock Shapes and Machined parts

PF03

COMPOUND: PF03

POLYMER: Phenolic

DESCRIPTION: High Strength Long Glass Fiber Reinforced Phenolic Compound, Molded and Machined parts, Black Colored

PF15

COMPOUND: PF15

POLYMER: Phenolic (Thermoset)

DESCRIPTION: Glass Fiber Reinforced Phenolic Compound, Black Colored